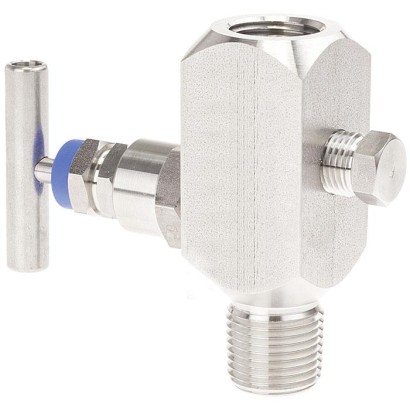

Needle valve and multiport valve

Part number: Models IV10, IV11

Applications of the needle valve

- Shut off and vent pressure measuring instruments

- For gaseous and liquid aggressive media that are not highly viscous or crystallising, also in aggressive environments

- Process industry: Oil & gas, petrochemical, chemical industries, power generation, water and wastewater

Special features of the needle valve

- Low-wear design due to non-rotating spindle tip in the bonnet

- Low torque and smooth operation of valve handle even at high pressure

- Enhanced safety due to blow-out proof bonnet design

- Valve seat tested for leak tightness per BS6755 / ISO 5208 leak rate A

- Customer-specific combination of valves and instruments (hook-up) on request

Description of the needle valve

Needle valves and multiport valves separate the process from measuring instruments such as pressure gauges, switches or transmitters. By closing this valve the instrument can be safely dismounted for services like recalibration or replacement. With the vent connection option, the instrument can be vented to the atmosphere by means of the needle valve. Already in the standard version, the multiport valve is equipped with two additional connections. These can be used either as vent connections or for the connection of additional instruments.

Through the non-rotating spindle tip, the wear of the sealing elements is reduced. This results, particularly with frequent opening and closing, in a noticeable increase in the service life.

Through the blow-out proof design of the valve, working safety is improved, especially in applications with high pressure loading.

As an option, WIKA offers the professional assembly of valves and pressure measuring instruments and also other accessories into a ready-to-install solution, also known as a hook-up. To ensure the performance of the complete system, an additional leak test is carried out on the hook-up.